Exploring the functionality of metallized papers

Functionality and premiumization

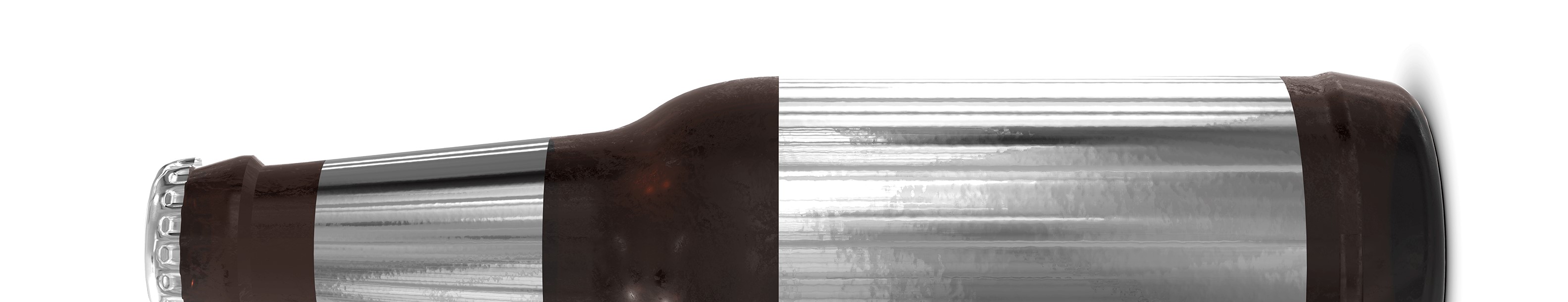

AR Metallizing’s origins are in metallized paper beer labels. As brands realized the premium appeal afforded by metallized papers, our range of products expanded. Today, we are a supplier of metallized and holographic papers for print and media, gift wrap, direct food contact packaging, cosmetics, labels, fashion and other applications.

But while our papers are celebrated for their glossy, vibrant looks, the world of metallized paper isn’t just about appealing packaging. It’s also very technical, and our scientific team have a certain amount of flexibility to create different functionalities and technical performance. As our ability to cater to specific applications evolves, more customers are coming to us to help support them with packaging or label looks that provide premiumization as well as functionality.

"A great example of the possibilities of our metallized paper, is our butter wrap."

‘While the metallization process and coating process don’t change, we have been able to select and combine the right raw materials to create a new, functional metallized paper material. We’ve achieved an excellent grease resistance, and our paper can withstand cold and humidity. Our butter wraps also have great dead folds. We accomplished this by looking at the science of our papers and changing coatings to increase performance. We hope a lot more like this is possible with metallized paper over time,’ explains Daniela Mondelli, PHD, R&D Director.

‘We’re keen to push technical boundaries with our papers.'

'Not so long ago, the idea of a recyclable, paper-based butter wrap was unheard of. Today, we’re bringing exactly that onto the market. Even better, we can offer comparable functionality to multi-layer alternatives in terms of performance. Developments like these are really exciting,’ says Valeria Rasetto PhD, product development manager.

Functionality: the bigger picture

Labels and packaging influence consumers to buy a product. So once a product is home with the consumer, isn’t our job done?

We don’t think so, and we don’t focus on a ‘snapshot’ of the supply chain. While keeping the needs of printers, converters and the end-user central, we believe there’s a solid case for us to think further.

With beer labels, for example, European brewers often have beer bottles returned to them for reuse. Wash-off time and performance are considerations that have operational, and efficiency repercussions if wash off takes too long. Likewise, if bottles go into a standard country or state-wide recycling process, we don’t want our papers to unnecessarily lengthen the recycling process due to wash-off times, which requires more energy.

‘Part of our values and our strategy is always to look at the bigger picture,’ says Valeria. ‘Once our papers get to the recycling phase, we still believe that they should be efficient to recycle and stay within the norms of what might be expected for a ‘plain’ paper. We work hard to develop our papers to be efficient for the recycling process,’ Daniela concludes.

Can we help?

If you have questions, comments or would simply like to know more about our metallized papers, drop us a note...we'll be right in touch!