How can you achieve luxurious looks with paperboard?

When it comes to packaging, glossy good looks help attract consumers’ attention and make products stand out on the shelves. However, metallized finishes can come at a cost, while raising questions about manufacturers’ environmental credentials.

One of the most widespread processes used to achieve metallized packaging and labels involves laminating board with “MetPET”, or metallized polyester film. While widely available and relatively cost-effective, MetPET comes with its downsides: the end result is dependant on the quality of the board substrate it is laminated to, “memory” - i.e a tendency to ping back - can hinder its folding performance, and base materials are contaminated by raw polyester, meaning they need to be separated before recycling and more often than not end up in landfills.

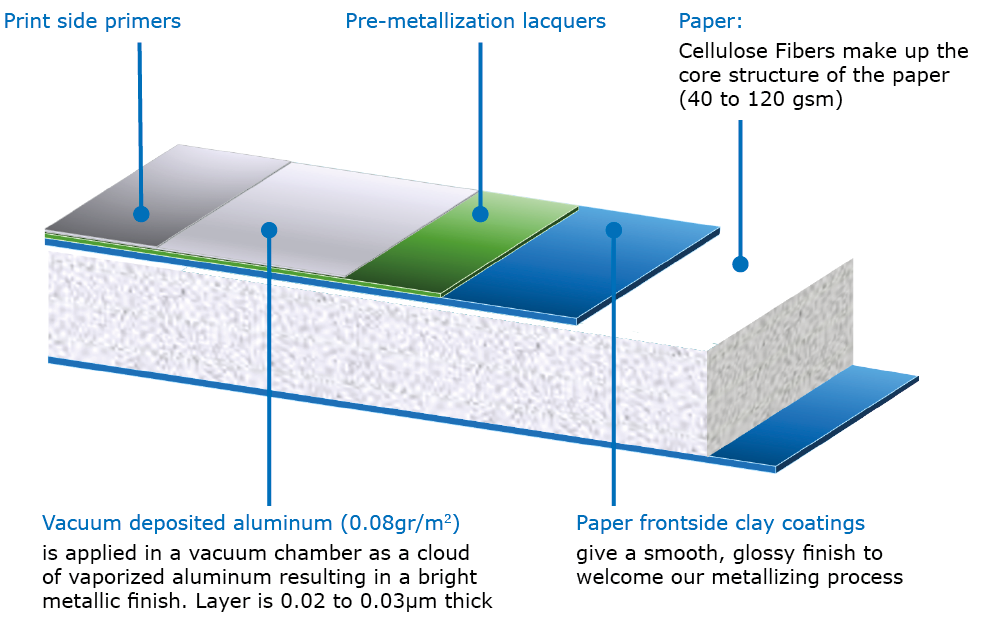

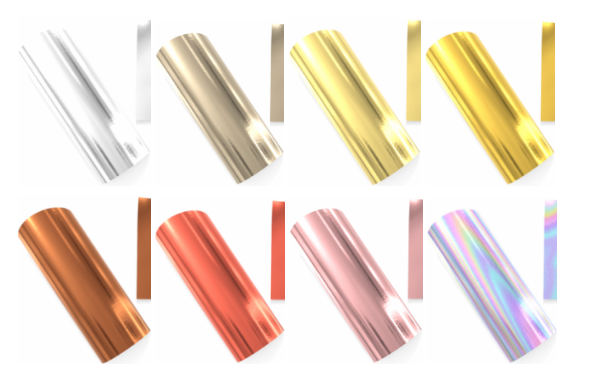

Fortunately, metallized paper offers a viable alternative to foils, with comparable technical performance, global availability, low-waste production processes and 100% recyclability. Metallized paper draws its shine from several sources: its base substrate (i.e the paper itself), a microscopically thin layer of aluminium and its top coating. What’s more, the excellent foldability of metallized paper makes it ideal when used in conjunction with boxes, such as secondary packaging with foldable flaps or ecommerce subscription packaging.

The AR Metallizing team would be happy to help your company make the switch to metallized paper. To find out more, get in touch.