How Companies Can Transition From a Linear to a Circular Economy

Nissha Metallizing Solutions are strongly committed to environmentally responsible manufacturing (or ERM), which aims to ensure our products are manufactured and provided with as little environmental impact as possible. Our approach involves i.a.: reducing waste from manufacturing processes, limiting our consumption of finite resources and transforming waste into input for other processes. This approach is known as circularity - let’s take a look at what that entails.

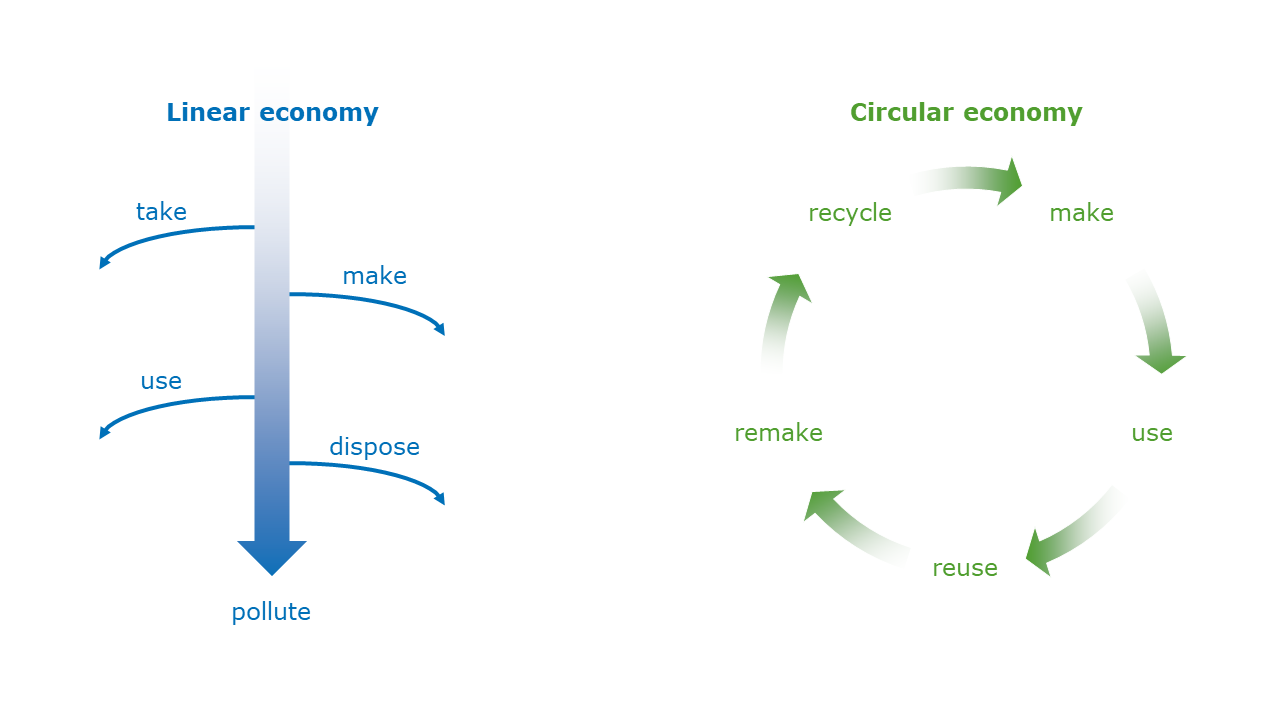

What’s the difference between the linear and circular approach?

Traditionally, manufacturing processes run in a straight line from design to disposal - hence the term “linear economy” - creating waste at every stage of the pipeline. A circular approach, on the other hand, involves rethinking processes so as to reintegrate waste and turn it into energy or new products, ideally so that none is left over - therefore “closing the loop”.

Making the transition to a circular economy

Transitioning to a circular model is a major shift that requires significant investment, systemic thinking and collaboration. Ultimately, each business is different, and there is no one-size-fits-all solution. But with this in mind, here are three steps companies can take to move closer to circularity:

- Design for durability, re-use and recyclability, therefore keeping products and materials in the loop for as long as possible, and therefore out of landfills. For example, all our packaging materials are based on plastic-free metallized paper, enabling it to be easily recycled via conventional recycling streams.

- Optimise your energy use and decrease your dependence on fossil fuels, for example by switching to LED lighting or opting for electric vehicles. Here at Nissha Metallizing, we reduce our emissions through photovoltaic power, smart lighting and energy optimization policies.

- Be transparent and inform staff, clients, suppliers and investors about your commitment to a circular economy.

With all this in mind, be aware that circularity cannot be achieved overnight and is rarely a perfect circle: in most cases, circular models do not operate as immaculate closed loops. Circularity is a continuous process of improvement and growth in which companies identify and implement ways to capture ever more value from resources. Interested in finding out more about Nissha Metallizing Solutions’ approach to circularity and environmentally responsible manufacturing? Don’t hesitate to drop us a line.