Measuring metallized paper gloss

Gloss. High shine. Polish. All exciting words, but without any science to back up the terms, they’re relatively subjective adjectives. Gabriela Ribeiro explores the science & testing behind our gloss finishes.

Outside of the paper and packaging industry, describing something as 'glossy' is subjective, but usually, it doesn't matter too much if opinions differ. For brands, printers and converters, the gloss of packaging is vital, and it must be measurable. Gloss is crucial to achieving maximum shelf appeal, premiumization and desirability.

'There are also other considerations,' says Gabriela Ribeiro, R&D Manager at AR Metallizing in Brazil. 'How can a packaging designer or marketing team convey just how glossy a metallized label or packaging material is without a universal scale, for example? There are also cultural considerations: what if 'glossy' in America means something different in Europe or Asia? And lastly, if we didn't have any science behind our measurements, how as a supplier could we be sure that we consistently deliver the same level of gloss? Therefore, gloss measurements are a key feature of our regular quality testing,' says Gabriela.

Our products are tested to ensure that the quality is perfect and the gloss is consistent, both all over the same roll of paper and between rolls. 'From a technical perspective, we want to be sure that the quality of our product is maintained over time – what we produce in January for a customer can't be different from what we make for the same company in June,' explains Gabriela.

So how is gloss tested?

In-house, AR Metallizing uses glossmeters to test for gloss consistency and quality – papers from our Brazil, USA, Belgium and Italian plants are all lab tested for gloss.

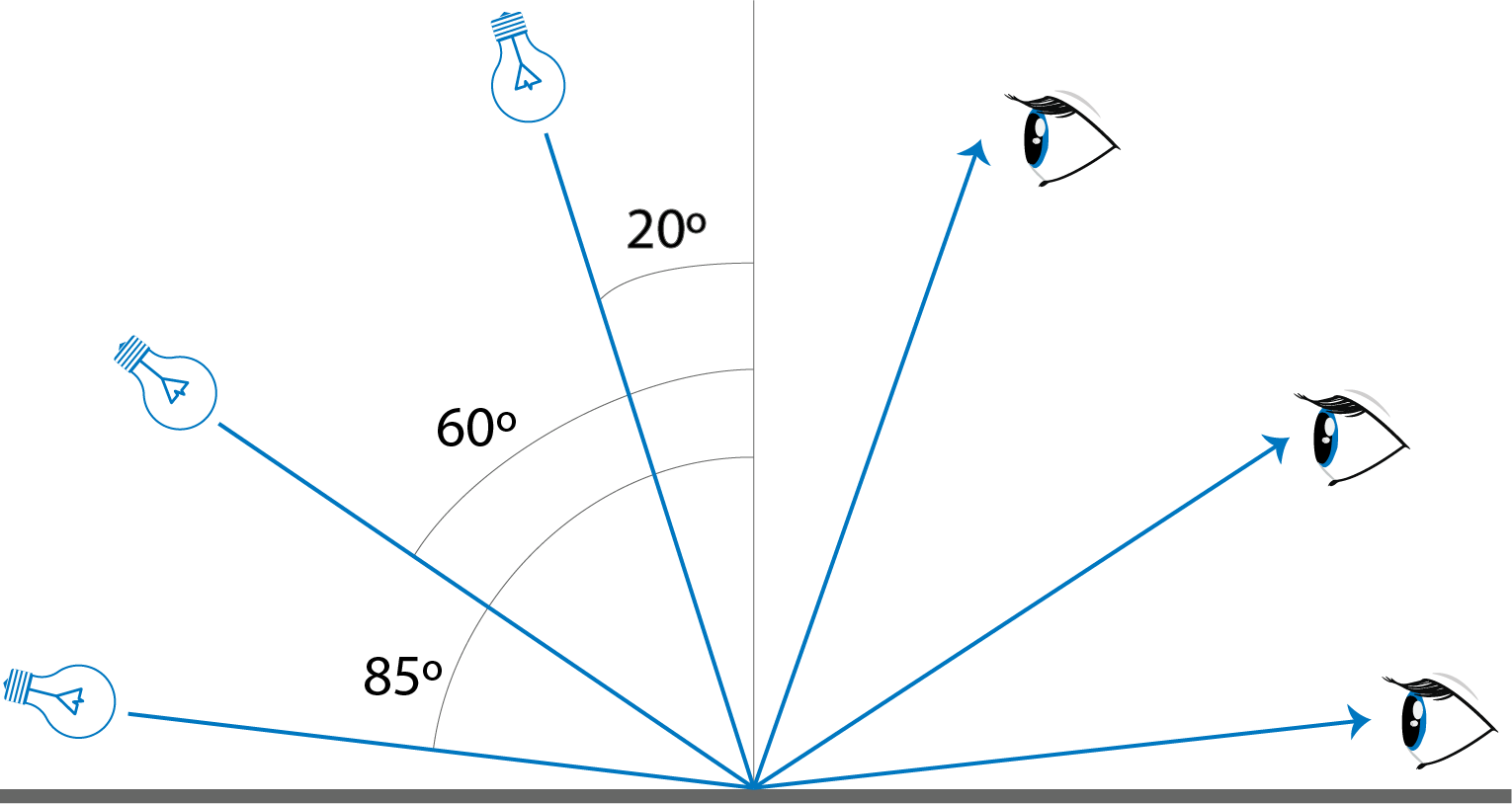

In essence, a glossmeter tests the amount of light that is reflected from the surface of our papers in Gloss Units ('GU'). The gloss meter shines light onto the metallized paper at a specific angle and then tests and the amount of light reflected from the paper at an equal angle.

Gloss measurements fall into three categories: high gloss, semi-gloss and matt. The higher the gloss unit ('GU'), the more reflective the material and the clearer the reflection.

High gloss materials typically have a GU of 70 or above, semi-gloss sits between 10 and 70 GU and matte is below 10 GU. For semi-gloss materials, the 60° angle is typically used on the glossmeter. For low gloss materials, the glossmeter usually tests at an 85° angle, and 'high gloss' is measured using a 20° angle on the glossmeter. Typically, despite having a specified gloss level, materials will be tested at 20, 60 & 85° so that the end-user can have an understanding of scope the gloss of the material.