In-mold labelling

In-mold labelling is typically considered one of the most niche label application methods, accounting for just 2% of the labeling market share. Compared to the nearly 40% market share of PSL, IML seems like a small sector of the industry, but it’s expected to grow to more than USD 4 billion by 2026 and demand is increasing steadily.

‘Demand for IML is principally driven by consumers and brands. IML is common in a number of consumer goods sectors: motor oil, laundry detergent, dish washer pellet packaging and food packaging, and we can expect brands in various sectors to use IML more and more, especially as they find trusted partners to work within the supply chain,’ explains Lindsey Barbee, National Account Manager, AR Metallizing. Since IML film labels do not cause contamination during the recyclability process, this is also a motivating factor for a number of brands with strong sustainability initiatives,’ adds Lindsey.

While consumers typically enjoy the finished IML application and brands appreciate the practicality of IML packaging, getting all players to work together to achieve a perfectly labelled vessel is a top priority.

‘When introducing our papers and films for IML applications to anyone on the supply chain, we often field questions related to application and performance at all points along the supply chain,’ explains Lindsey. ‘Breaking this down, we might see paper or film efficiency on printing presses being a key concern for printers, so we formulated our coatings to dial in on desired coefficient of friction (COF), which helps with flow through converter equipment and maximizes impression per minute. For bottlers, we address questions or potential issues such as waste ratios on label lines and label pinning techniques.’ she adds.

Blow and injection IML

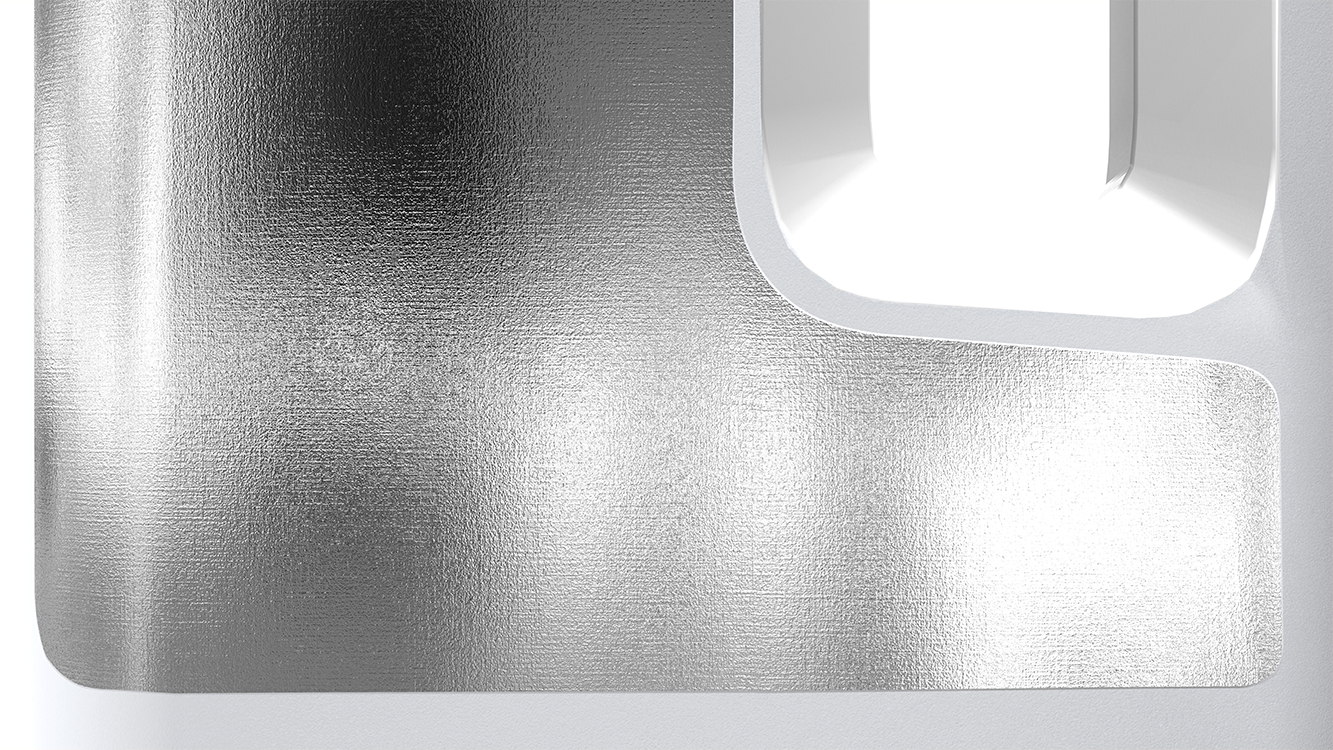

AR Metallizing produces a variety of metallized films and papers, and our product line offers solutions for both blow and injection IML applications. As a trusted and experienced IML film and paper supplier, our team is well-positioned to be able to support new customers with their IML applications, or those that wish to move from white or clear labels to a premium metallized or holographic look.

Our portfolio of IML products is optimized for both printing/converting equipment and label applications. Our grades have been designed with technology to maximize performance through sheetfed offset presses, we have focused on proper airflow to ensure effective feeding into presses. Inks are important, and we are on hand to provide advice on the right inks for use in conjunction with our products – especially if a customer is making a move from paper to film. All this said, every application and IML process is different, and therefore our expert team of researchers and developers refine the technical characteristics of our films or papers to ensure that they are ideally suited for specific IML applications.

The products we supply offer complete peace of mind

Above all, IML is a scientific and technical application, and the harmonious performance of IML components and machinery is vital for all parties within the supply chain, as is working with the right partners to support the perfect application for the end product. ‘Getting IML applications right takes testing and perfecting, and it is something we are dedicated to achieving, especially to ensure that the quality of the IML application meets the stringent technical requirements. Understandably, it can be a nightmare for brands if their product is already in the market and then the IML process develops issues on subsequent print runs or during the molding process, so we always work hard to ensure that the science behind our products is sound so that our customers can be sure about the ongoing validity of the products we supply offer complete peace of mind,’ says Lindsey.

Technicalities aside, metallized films and papers bring several other exciting benefits for brands. ‘Our films and papers undoubtedly add shelf appeal and a premium look to packaging, which is highly desirable in the competitive markets where we typically see IML applications. As well as their technical properties, our products also offer some unique features. One of our most appealing finishes, is our holographic solutions, which offer brands unique looks that are not readily available within the IML market at the moment,’ says Lindsey.