Myth busting: what is metallized paper and exploring some common misconceptions

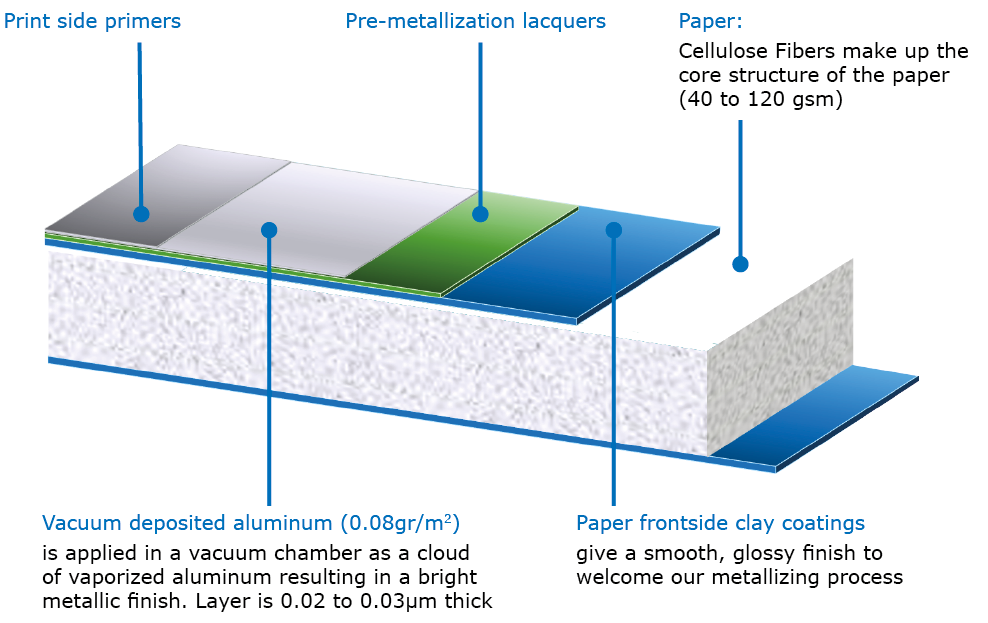

Metallized paper has a microscopically thin layer of aluminium (approximately 20-30 nm thick) evaporated onto its surface. The layer of aluminum gives the paper a bright, glossy surface which is visually appealing – meaning it’s ideal for packaging and labels.

Despite the addition of the aluminum layer, our products remain a paper material from a technical standpoint – because the aluminum layer is so thin, it doesn’t change the overall composition of the material.

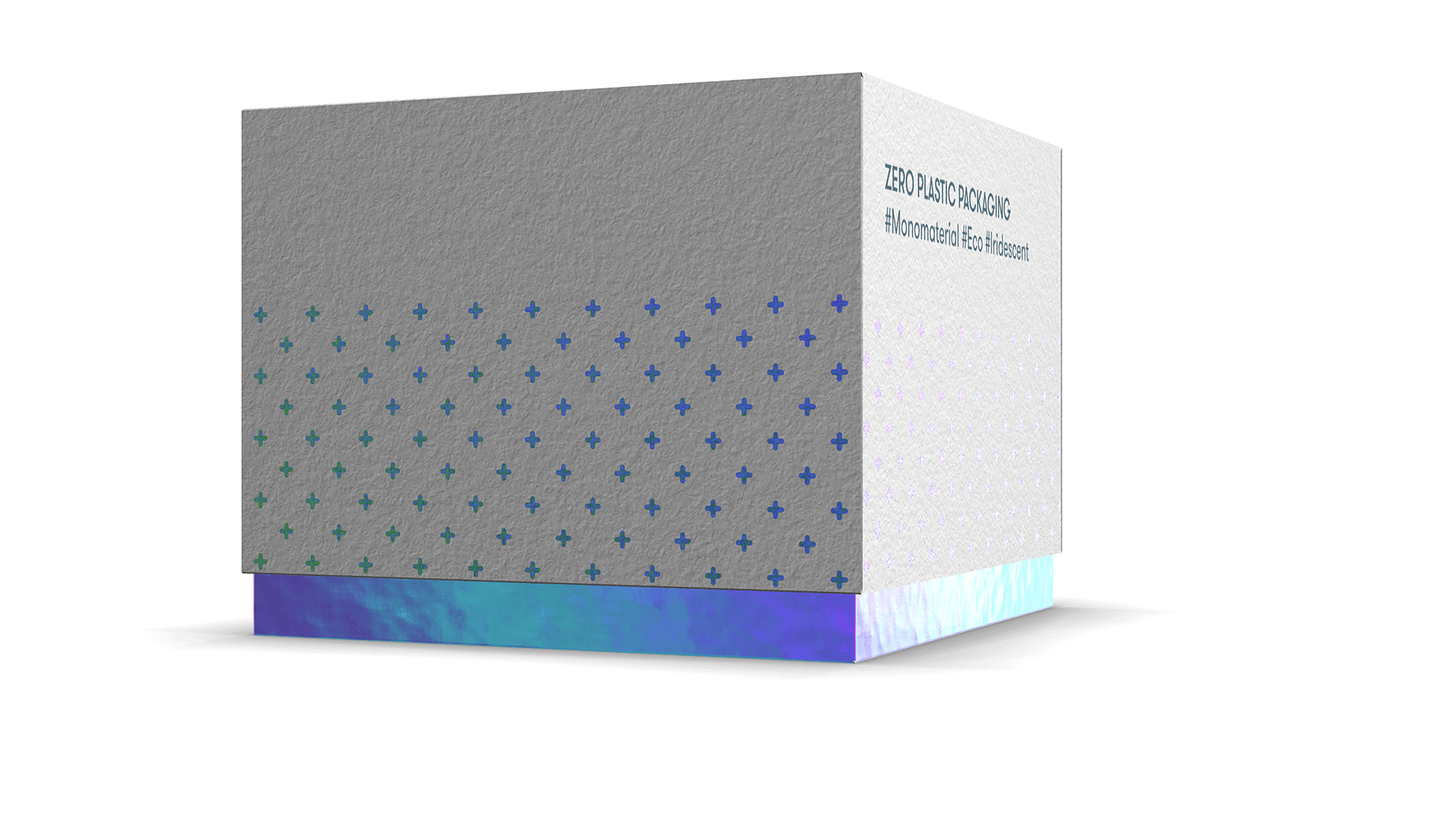

While metallized papers were originally used for packaging because they offered shelf appeal, they also offer other benefits, namely some advantageous barrier properties, excellent resilience and approval for some direct food contact packaging. Metallized paper is recyclable and an excellent alternative to metallized PET films for brands looking to reduce plastic.

Common misconceptions about metallized paper:

- It’s important to know that metallized paper isn’t anything like aluminum foil or aluminum paper laminate. Our products retain the texture and tactility of paper, with the addition of the very smooth, silver surface – imagine a kind of ‘mirror effect’ on a paper substrate.

- Metallized paper producers – like Nissha Metallizing Solutions – typically aren’t printers or converters. We are specialists in our field, and we produce large rolls of metallized paper. Printing and converting functions are carried out by trusted partners on the supply chain who create the packages or labels for end-users.

- We manufacture metallized paper in a single color: silver. It’s easy to make any type of metallic hue or shade by printing in transparent inks over the top of our papers, but we don’t produce in different colors.

How is metallized paper made?

- We apply a base varnish to paper to increase gloss level and seal the pores inherent with the paper. The base varnish creates a very smooth surface for us to metalize.

- After pre-coating, we metallized the paper. A microscopically thin layer of aluminium, approximately 20-30 nanometers thick, is evaporated on paper in a vacuum chamber.

- When the paper has been metallized, we carry out post-coating and roll-finishing, which provides a degree of abrasion resistance and a printable surface onto the metallized substrate.

Holography

Because our papers are metallized, we are also able to create holographic papers. Base papers are pre-coated and then embossed with custom or ready-made patterns and then metallized. The paper is then post-coated. As natural white light hits the indentations and hollows in the embossed metallized surface, they diffract light, creating the effects we recognize as holography.

We'd love to hear from you

If you have questions, comments or would like to know more about our papers, products and processes, drop us a note!