Using inks with metallized paper

One of the main advantages of our metallized paper is that it can be printed with the same inks as conventional paper, giving designers flexibility while causing minimal disruption to existing converting processes. Our metallized papers are manufactured in silver and then printed with inks to create varied shades, with different levels of opacity used to create different effects. Here’s how that works:

- Printing metallized paper using standard CMYK will create a solid appearance and bold, jewel-like tones.

- Transparent inks will add a layer of colour that retains the glossy metallic look of the paper below.

- Using varying levels of opaque white ink under colours enables printers to fine-tune the glossiness of the end product. Low opacity (zero to 40%) will create a shiny effect that lends itself well to products that need stand-out shelf appeal. The 50-70% opacity range offers a more subtle and muted look, while 100% opacity will create a solid, pristine white surface.

- Opaque black ink produces striking results when combined with metallic show-through in select areas of the design.

- The primer we apply on the top after metalization make our metalized paper universal printable.

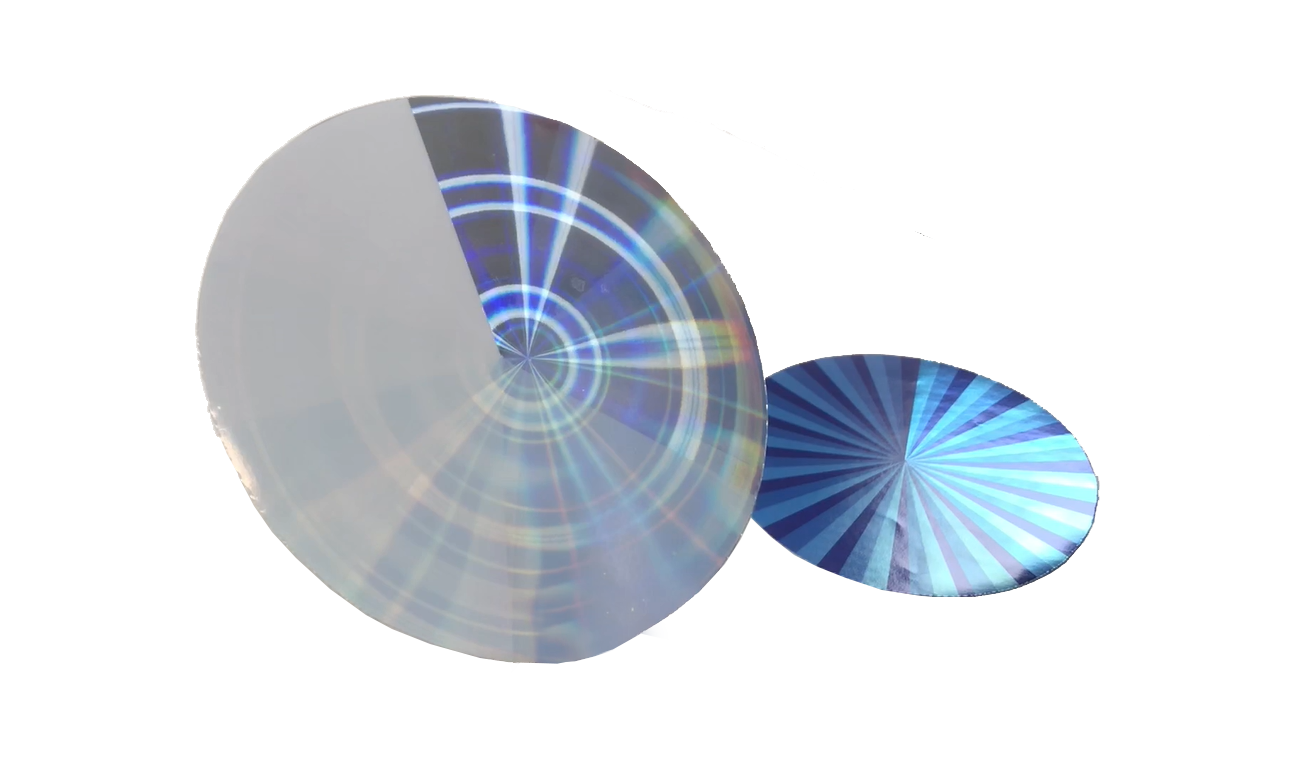

- Holographic paper can also be printed with white ink to make the design stand out more or less, as needed. But did you know that the colours people perceive in holographic paper are actually due to the light refraction effect, rather than printed inks?

To find out more about how metallized paper offers you maximum flexibility to create stunning designs, get in touch with our team.