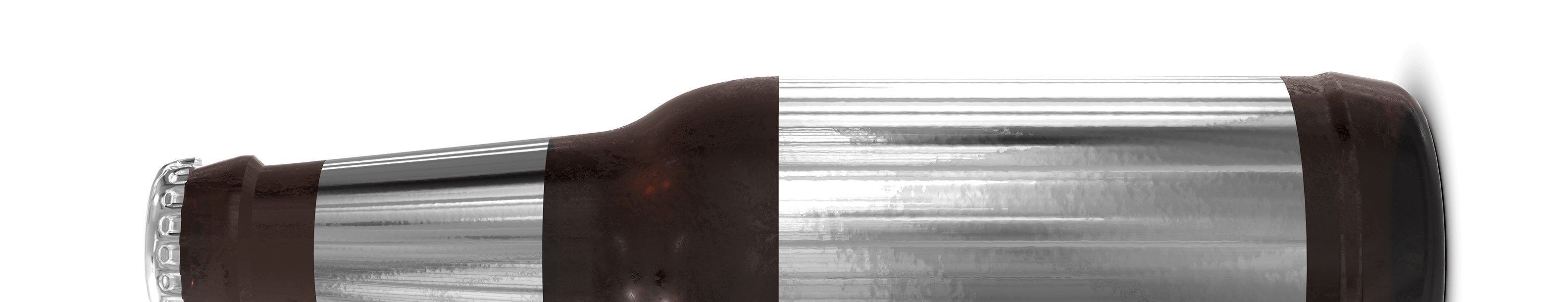

Wet-strength labels: exploring wash off requirements and technicalities

For many consumers and brewers glass beverage bottles are simply recycled by the consumer, and, until now, there hasn’t been much of a market for reusable glass bottles. The result is that wash off rates aren’t much of a consideration, whereas wet-strength label performance is a more mainstream topic.

Why do wash off rates and performance matter?

Reusing glass bottles – particularly in the beer industry – is common in a number of countries. Bottles are returned to breweries, washed and then refilled. While it’s not a conventional practice in much of the world, it remains a big component of the market, with many breweries seeing advantages in recycling bottles, rather than sourcing new ones.

As more companies look to operate in a circular economy, we may also see some uptake in the number of brewers committing to reusing their bottles.

Wash off rates: key factors that matter for brewers handling returned bottles

The requirements of the wet-strength labels aside and focusing on wash-off requirements, brewers are looking for base paper that supports labels to:

- Maintain their integrity in the caustic wash-off solution

- Have excellent ink retention performance

- Support an optimized washing machine speed line

- Lower the number of rejected bottles (those that come out of the alkaline solution with labels fully or partially attached)

- Support excellent wash off times with both casein and synthetic glue

Technical requirements: understanding modern glue behavior

Over the past years, glue trends for wet-strength label applications have changed and developed significantly. Where casein glues were typically the ‘go to’ of the past for wet-strength label applications, they are increasingly being replaced by synthetic glues.

Synthetic glues have excellent ice water resistance. Their superior qualities were identified when they were initially used in tropical countries where beers are sold on the streets in ice water buckets.

Although they offer optimal ice water resistance, sometimes synthetic glues can take longer to wash off in caustic solutions than casein glues, which slows the recycling process. Nissha Metallizing Solutions' specialized paper for wet-strength labels "RotoFLEX" have reduced the wash off time for synthetic glues – a distinct advantage for brewers and beverage producers.

Due to competitive cost advantages, synthetic glues have grown in market share in the beverage industry, also in Northern Europe, South East Asia, Latin America and Africa. Casein glues are still used however, and producers of wet-strength label materials like Nissha Metallizing Solutions need to have a base paper that can reliably meet the requirements of brewers using either casein or synthetic glues.

Nissha Metallizing Solutions offers brewers and beverage companies high-quality and advanced label papers

In order to be able to best support brewers, Nissha Metallizing Solutions has developed a metalized paper for paper wet-strength applications that has excellent wash off times (for both casein and synthetic glue) and can maintain high ink retention performance.

Using Nissha Metallizing Solutions RotoFLEX paper, our clients can benefit from similar wash off times regardless of whether their application uses synthetic or casein glues.

Our optimized wet-strength paper will support breweries to increase washing machine speed line, increasing their productivity but avoiding the risk of rejected bottles.

Naturally, the paper has all the technical characteristics required for wet-strength labels in ice bucket conditions.